Petrochemical materials Export

Today, Petrochemical materials Export has become more important than ever. These materials are among the materials that can be exported to neighboring countries such as Iraq, Afghanistan, Georgia, Pakistan and… This is the reason for the importance of producing and exporting chemical raw materials. The target market for downstream products is petrochemical raw materials, which has a wide range.

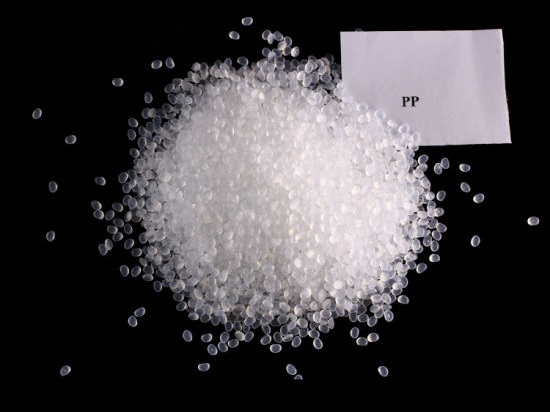

For example, polypropylene (PP) is a thermoplastic chemical that results from the polymerization of propylene and is also recyclable. It was first produced in a laboratory comparison in the early 1950s and reached commercial production later in the decade. The following is a description of this type of petrochemical:

Learn more about polypropylene petrochemicals

Polypropylene is one of the most widely used and basic polymers used in the world and the largest consumer of propylene. The name of this product is polypropylene (PP) and its chemical formula is -CH2-CH (CH3) n-. Polypropylene is a thermoplastic polymer. The propylene molecule has an asymmetric chemical structure.

It is resistant to moisture, oils and ordinary solvents and melts at a temperature of about 170 degrees Celsius. Polypropylene has three different spatial configurations: isotactic (iPP), syndactic (sPP) and atactic (aPP). The highest crystalline properties of these grades are related to isotactic, syndactic and atactic infrastructure, respectively. As follows:

Isotactic

In this structure of polypropylenes, methyl groups are located on one side of the main chain. The isotactic structure has a high melting point and is a crystalline, tough material.

Syndiotactic

In this structure, the methyl groups are arranged one at the top and bottom of the main chain. This substructure has the same properties as the isotactic substructure but is clearer due to its lower crystallinity. It is also more difficult to process than other grades.

Atactic

It has a low melting point substructure and is a resinous substance. Due to its high adhesion properties, it is used in the manufacture of some adhesives. In this structure, methyl groups are randomly located on both sides of the main chain. It has a low melting point substructure and is a resinous substance.

Due to its high adhesion properties, it is used in the manufacture of some adhesives. Atactic polymer is an amorphous, flexible and rigid material. In contrast to isotactic and syndactic polymers, high-crystallinity polymers are harder and less flexible.

Petrochemical materials Export with Tamin Paydar Commercial Group

Polypropylene petrochemical material standards

Export of Polypropylene Petrochemical Materials Based on the International Organization for Standardization (ISO), the American Materials and Testing Association (ASTM), the German Standards Institute (DIN) and the National Standards Organization of Iran (INSO), there are several standards for evaluating the quality of various polypropylene products. To export these products.

These standards include a variety of polypropylene grades. And by formulating basic standards in the field of polypropylene products, it has provided a clear guide to manufacturers, which includes life-pressure-temperature-physical-geometric, mechanical-mechanical-size, etc. curves.

Types of polypropylene

Polypropylene petrochemical materials are generally divided into two general categories in terms of grade, which are:

Homopolymers

Polypropylene homopolymers as mentioned. Based on their spatial order, they are divided into three categories: atactic (disordered), isotactic (coordinated) and syndactic (single order). Polypropylene is a homopolymer produced by the polymerization of propylene monomer alone.

From the point of view of physical and mechanical properties, the difference between polypropylene homopolymer and copolymer in impact strength has more tensile strength and stiffness, but its impact strength is low.

Although polypropylene is a homopolymer with higher tensile strength and stiffness than polypropylene copolymer, its main disadvantage is its impact resistance. In fact, homopolymer polypropylene is more brittle than copolymer polypropylene. This weakness is more pronounced at low temperatures, especially below zero.

Therefore, the use of polypropylene homopolymer in the production of injection parts that are exposed to impact and low temperatures is severely limited. Homopolymer is brittle and shows itself more when the temperature is low, especially below zero.

Copolymers

Copolymers typically consist of two or more different monomers. This type of polypropylene contains a very small amount of butylene and hexane ethylene. Polypropylene copolymer produced from the polymerization of propylene with the ethylene commonomer. Polypropylene copolymer has a higher impact resistance than polypropylene homopolymer.

By adjusting the amount of ethylene added to the polymer structure, adjusting the morphology of the copolymer, adjusting the type of crystallization as well as adjusting the molecular weight, the impact strength can be adjusted and increased to a good extent.

Of course, it should be noted that increasing the impact resistance of polypropylene is done at the expense of reducing the hardness and rigidity of the polymer. Adding ethylene to the polypropylene structure during the polymerization of propylene reduces the structural order of the polypropylene. Reducing the structural order, in turn, reduces the crystallization rate of polypropylene.

Due to the fragile structure of crystals, the reason for the increase in impact resistance of polypropylene copolymer compared to polypropylene homopolymer is the decrease in crystallinity. There are two types of polypropylene copolymers used in trade, the most important of which are impact copolymers and random copolymers.

Petrochemical materials Export

Advantages of using and exporting polypropylene petrochemical materials

Like the export of polyethylenes or all petrochemicals that have a number of special advantages. Polypropylene also has its own advantages, which include:

No sedimentation of this type of petrochemical material

The smooth surface of these makes it easy for water or other fluids to pass through. This prevents fouling and prevents the fluid from dropping pressure. On the other hand, the molecular structure of polypropylene is similar. Which prevents the formation of sediment and disturbing substances in their ducts.

Resistant to stresses and high pressures

Polypropylene material has high stress resistance and high pressure resistance. Hence it does not suffer from cracks or fragility. Also, the thermal resistance of these pipes is very high and they will not have any problems up to 110 ° C and they will maintain their structure.

Resistance to chemical and natural substances

Polypropylenes are such that they maintain their chemical structure under natural environmental conditions. They are also highly resistant to many chemical corrosives, such as some acids and bases. To the extent that they can be used to transfer them.

Has a long useful life

The chemical resistance of polypropylene is very high. Therefore, this type of material will not rot over time and will maintain its strength. These materials naturally decay very late. It can even be said that the life of polypropylene materials is longer than the life of a building and a smart home. In other words, the life of the building is over, but the pipes can still be used.

Very low decay and erosion

Polypropylene materials are well resistant to water flow, defined drinking water temperature, water pressure and shocks from the fluid and do not corrode.

Of course, no material can completely avoid erosion, but the process of erosion and abrasion of these materials is so slow that this issue has practically no negative effect on them.

Reasonable and relatively cheap price

The price of this type of material is more suitable compared to other alloys, including metal. Due to its advantages and features, it has made its use in building facilities more economical and economical.

Petrochemical materials Export

Disadvantages of polypropylene exports

Polypropylene, like other materials, has many advantages and disadvantages. These disadvantages are as follows:

They disappear at high temperatures

If exposed to temperatures above 100 ° C, the polypropylene chain will be damaged and oxidation will occur. It will eventually cause them to crack. Polymer stabilizers can often be used to solve this problem.

Lack of resistance to sunlight

Propylene pipes are not resistant to direct sunlight and UV rays. Their chemical chain structure may collapse or weaken in the long run. To solve this problem, you can also use building coatings or insulation or put them in the shade.

High longitudinal expansion of petrochemical materials

Polypropylenes, unlike metal pipes or 5-layer, do not have a metal layer. This has caused their longitudinal expansion to be high in the free state. For this reason, these materials must be fastened to the wall with a fastener or placed under a cover of cement mortar. Cement mortar reduces the longitudinal expansion of polypropylene and prevents them from thinning.

Application of polypropylene petrochemical materials

Applications of this polymeric material include car parts such as dashboards, consoles, covers, shock absorbers, faceplates, batteries and many other parts. Also, polypropylene with high melting index is used for the preparation and production of various disposable and plastic containers.

Polypropylene is also used to make sports equipment, transport bags and sportswear. Grades with low melting index are also used to prepare hot and cold water pipes, etc.

Polypropylenes can also be used for medical products. For example, it is used to make disinfection bottles, syringes, pill containers, etc. Polypropylene is also used in the manufacture of home appliances such as carpets, mattresses, plates, toys or even accessories in washing machines, refrigerators, dishwashers, etc.

Opposite polypropylene is a homopolymer that has less impact resistance and high crystallization. As a result, they use it to make all kinds of thin sheets, textiles, and thin films. Hemopolymer requires more than impact resistance, strength and tensile strength.